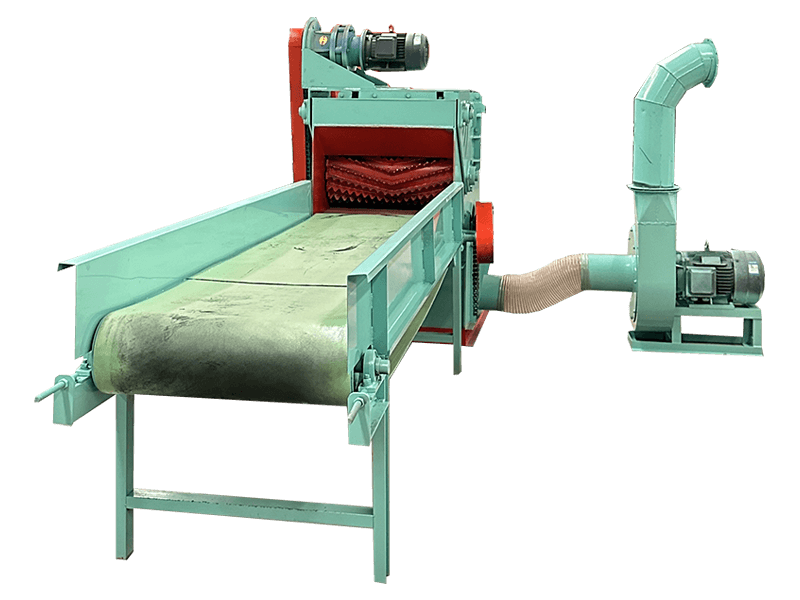

Forced feed wood pulverizer

Forced feeding wood crusher is also known as wood powder crusher, wood crusher, wood crusher, wood pellet mill, edge material crusher, tree branch crusher.

Capacity0.5-6t/h

Power22-90kw

Forced feeding wood crusher is also known as wood powder crusher, wood crusher, wood crusher, wood pellet mill, edge material crusher, tree branch crusher.

Capacity0.5-6t/h

Power22-90kw

Forced feeding wood crusher is also known as wood powder crusher, wood crusher, wood crusher, wood pellet machine, edge crusher, branch crusher, the machine is a production of wood powder before the process of ideal machinery and equipment, he can be timber, branches, wood, lumber and other raw materials once processed into wood chips, has the advantages of low investment, low energy consumption, high productivity, good economic efficiency, easy to use and maintenance, etc., is the development of edible fungi production or for particle board, sawdust board, high density board wood pellet production of raw materials. It is the special equipment for the development of edible fungus production or as particle board, sawdust board, high density board wood pellet raw material production. The machine can process wood, branches and forks and other raw materials into wood chips at one time, with the advantages of less investment, low energy consumption, high productivity, good economic efficiency, easy to use and maintain. The wood crusher is especially suitable for processing wood chips in the culture medium of edible fungi. The wood chips cut by the chip-cutting device are small in size and can be sent to the crushing device for further crushing without drying in the sun.

1. It is composed of three main parts: feeding mechanism, crushing chamber and discharging part.

2. The pulverizer is divided into two types: single-port and double-port.

3. attached by the fan, powder collector, dust collector.

4. the host crushing chamber by the rotor, hammer blade, screen; or knife plate, there are coarse crushing, fine crushing and centrifugal repetitive crushing, driven by the motor crusher rotor high-speed operation, so that the mechanical generation of high-speed airflow on the crushed material to produce high-intensity impact, compression, cutting force, friction, to achieve a unique crushing function.

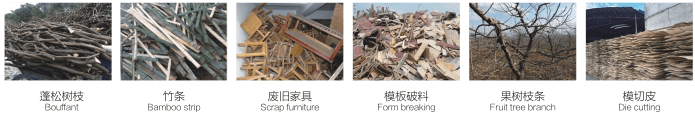

Wood crusher can be crushed pine, miscellaneous wood, wood, cedar, cedar, bamboo and other types of wood, can also be used for bamboo, thatch, corn stalks, sorghum stalks and other fibrous culm materials are widely used in papermaking, edible fungi, charcoal, particle board, sawdust board, high density board, medium fiberboard and other industries.

1. Improve the working efficiency, effectively save manpower and material resources;

2. At the same time safer, workers only need to throw material to the conveyor belt, avoid contact with the equipment safer;

3. Solve the problem of some branches and branches, or too long edges and corners, which can not be fed manually.

Performance Specification\Model | 500 | 600 | 800 | 1000 | 1300 |

Number of Hammer Blades | 30 | 40 | 60 | 70 | 100 |

Spindle speed(r/min) | 2600 | 2600 | 2400 | 2300 | 2300 |

Power(kw) | 22 | 30-37 | 45 | 75 | 90 |

Weight(kg/h) | 500-800 | 800-1000 | 1000-2000 | 2000-3000 | 3000-4000 |

| Overall dimensions(mm) | 2100x1320x1630 | 2150x1400x1730 | 2370x1400x1870 | 2700x1650x2000 | 2880x1940x2040 |