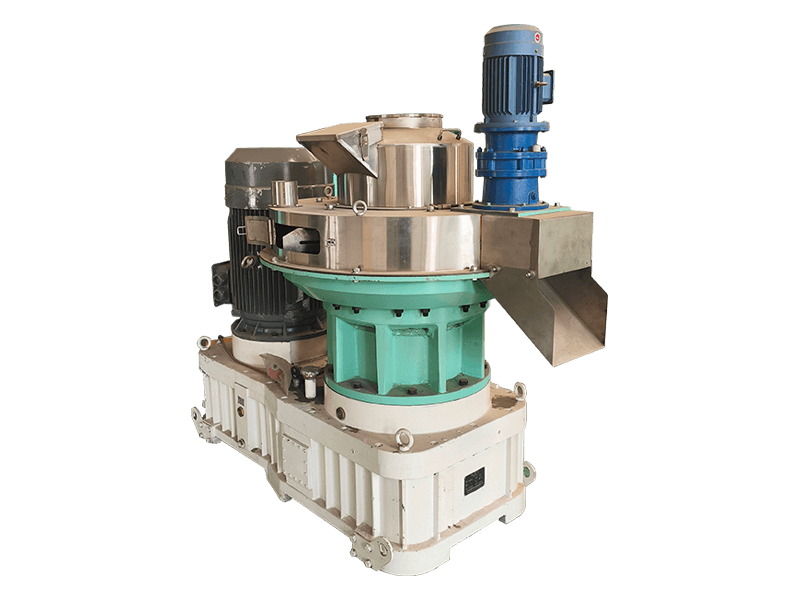

Biomass Pellet Machine

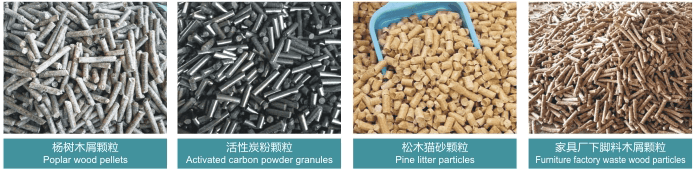

Biomass pellet machine is to tung wood, cypress, poplar, fruit wood and crop straw, bamboo shavings and other crushed into sawdust chaff, processed into biomass fuel equipment.

Capacity0.8-4t/h

Power55-220kw

Biomass pellet machine is to tung wood, cypress, poplar, fruit wood and crop straw, bamboo shavings and other crushed into sawdust chaff, processed into biomass fuel equipment.

Capacity0.8-4t/h

Power55-220kw

Biomass pellet machine is to tung wood, cypress, poplar, fruit wood and crop straw, bamboo shavings and other crushed into sawdust chaff, processed into biomass fuel equipment. Because of the different raw materials used in different places, biomass pellet machine in different places and called wood pellet machine, straw pellet machine, sawdust pellet machine, wood pellet machine, bamboo chip pellet machine, fuel pellet machine, straw pellet machine, rice husk pellet machine, etc., but also called the granulator, granulator, although called differently, but are the same kind of machine.

1、Biomass pellet machine can produce all kinds of wood chips, straw, husk and other raw materials based on biomass particles;.

2, the use of cooling molding, extrusion molding and other molding technologies, grease polishing and shaping process makes the biomass particles beautiful appearance, compact structure.

3、Biomass pellet machine has high output, low energy consumption, low noise, low security, strong machine fatigue resistance, continuous production, economic and durable;.

4、The whole machine adopts special materials and connecting shaft transmission device, the key components are made of alloy steel plus wear-resistant materials, utilizing German vacuum furnace heat treatment, the service life is extended by 5-7 times.

Adopting the principle of extrusion and friction interaction between the press wheel and the mold, the material can be shaped. There is no need to add any additives or binders in the process. Straw and other materials contain specific cellulose and lignin, and its lignin is the structural monomer in the material, which is a polymer compound of phenylpropane type. Lignin is the structural monomer in the material, and it is a polymer compound of phenylpropane type. Lignin is non-crystalline, the main part is insoluble in any solvent at room temperature, has no melting point, but has a softening point. When the temperature reaches a specific value, lignin softening adhesion increases, and under specific pressure, the cellulose molecular group dislocation, deformation, extension, internal adjacent biomass particles engage with each other, recombination and compression molding.

Raw material collection → raw material crushing → raw material drying → mechanical pelletizing and molding → mechanical cooling → bagging and selling. Depending on the harvesting period of crops, large quantities of raw materials should be stored in time, and then crushed and molded. When molding, pay attention to not immediately bagging, due to the principle of thermal expansion and contraction to be cooled for 40 minutes, and then bagged for transportation.

1. the use of high-precision involute cylindrical helical gear direct transmission, transmission efficiency is as high as 98% or more.

2. the transmission gear tooth blank water forging after normalizing heat treatment, improve the hardness of the tooth surface; tooth surface carburizing treatment, carburizing layer as deep as 2.4mm to enhance the wear resistance, prolonging the service life of the parts; hardened tooth surface by the silent grinding edge repair process, so that the operation of a quieter, smoother.

3. the main shaft and the connecting hollow shaft are made of German imported alloy structural steel by water forging, rough turning, heat treatment, fine turning and fine grinding, with reasonable structure and even hardness to improve the wear resistance of the parts and provide more reliable guarantee for the safe operation.

4. the host box using steel casting, thickness uniformity, compact structure; and then carefully processed by the Swiss imported CNC machining centers, processing precision zero error. Provide more powerful support for normal operation.

5. the transmission part of the bearings and oil seals used in Japan imported high-precision bearings and U.S. imports of wear-resistant and temperature-resistant fluorine rubber oil seals, and special additional lubrication back to the oil system, oil circulation and cooling, automatic oil lubrication at regular intervals. Ensure that the bearings are fully lubricated, more secure and reliable operation.

6. particle molding system bearings used in high-quality silent bearings, and increase the thin oil cooling lubrication system, bearing service life longer, safer operation.

7. The ring mold is made of high grade stainless steel and high nickel steel, and the unique compression ratio is designed reasonably, which makes the product quality better and the service life of the ring mold longer, and reduces the production cost.

8. The new generation of biomass biomass pellet mill is designed by Tongchuang designers, specializing in all kinds of biomass pelletizing. The company has its own production base, the ring die 560 # biomass pellet mill is in the factory after hundreds of tests and demonstrations, to determine the reliable, safe and economical model, the equipment can be a long time continuous operation.

Biomass pellet machine is a kind of pellet fuel molding machinery with all kinds of branches, wood, wood chips, corn stalks, straw stalks, wood chaff, wood flour, sawdust and other agricultural wastes as raw materials, the pellets made by this machine can be used in fireplace, boiler, biomass power plant.

| Model | Power(KW) | Capacity(T/H) |

|---|---|---|

| PD-450 | 55/75 | 0.8-1 |

| PD-560 | 90/110 | 1-2 |

| PD-560 | 132 | 2-2.5 |

| PD-700 | 160 | 2.8-3.2 |

| PD-850 | 220 | 3.5-4 |