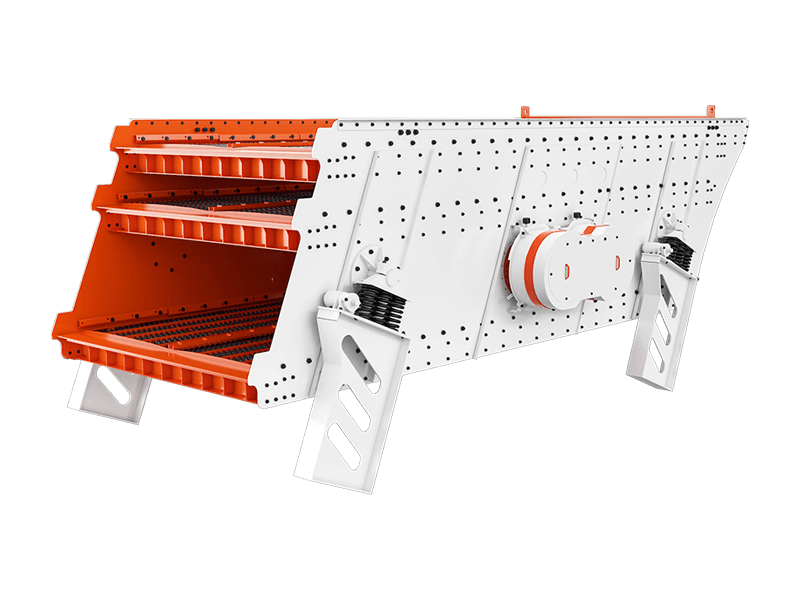

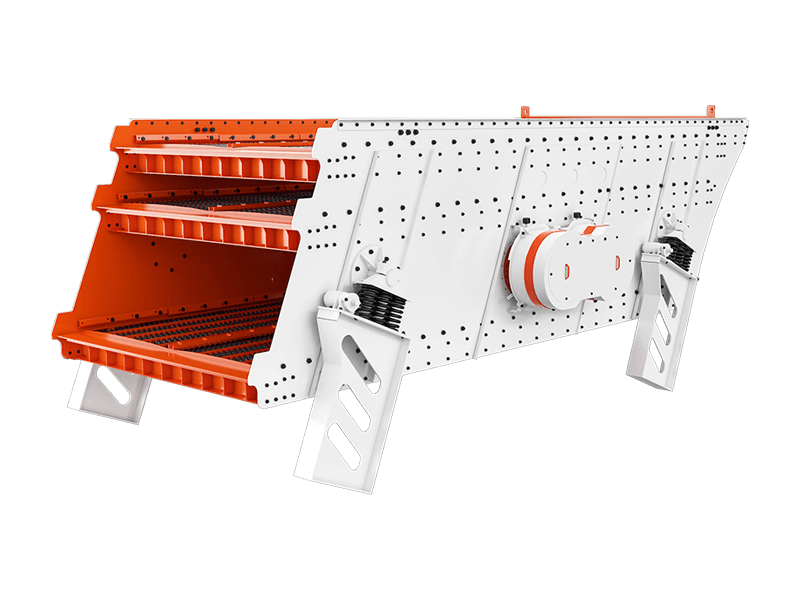

Vibrating Screen

Vibrating screen separator is kind of vibrating screen equipment with the multi layer, high production capacity and high efficiency.

Capacity30-850t/h

Feeding Size3-150mm

Vibrating screen separator is kind of vibrating screen equipment with the multi layer, high production capacity and high efficiency.

Capacity30-850t/h

Feeding Size3-150mm

Vibrating screen separator is kind of vibrating screen equipment with the multi layer, high production capacity and high efficiency. Vibrating screen is widely used in the mining, building materials, chemical, energy, metallurgy, environmental protection industries for the screen classification of granite, limestone, basalt, bluestone, quartz, hornblende, diorite and other materials.

1. High screen strength of the sieve box reduces the sieve pore blocking phenomenon, improving the screening efficiency and producing capacity;

2. Simple structure and convenient screen surface replacement;

3. Low power consumption of the per ton material screening;

4. High disposal ability and screening efficiency;

5. Having the vibrating shaker screen of varying models and vibration ways custom-made.

Vibrating shaker screen not only can be used in the mining and sand industry, sand screening of stone pit, but also in the production classification in power, coal, dressing, building materials, and chemical industry.

1. Start the vibrating screen separator only when no material is in the screen surface. Avoid boot with material and feed on the screening smooth running. Stop feeding before the machine halt. Close down the working machine when no material in the screen surface.

2. Inspect the screening running status frequently. Prompt shutdown inspection and trouble clearing are necessary when abnormal working and abnormal noise happen.

| Model | Screen Surface Specification(mm) | Layers | Feeding Size(mm) | Sieve Pore Size(mm) | Capacity(t/h) | Power(kw) | Vibrating Frequency(r/min) | Stroke(mm) |

| 2YZK1237 | 3700×1200 | 2 | ≤400 | 3-50 | 30-100 | 5.5 | 970 | 5-9 |

| 3YZK1237 | 3700×1200 | 3 | ≤400 | 3-50 | 30-100 | 7.5 | 970 | 5-9 |

| 2YZK1548 | 4800×1500 | 2 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 3YZK1548 | 4800×1500 | 3 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 2YZK1848 | 4800×1800 | 2 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 3YZK1848 | 4800×1800 | 3 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 4YZK1848 | 4800×1800 | 4 | ≤400 | 3-80 | 56-330 | 22 | 970 | 5-9 |

| 2YZK1860 | 6000×1800 | 2 | ≤400 | 3-100 | 65-586 | 18.5 | 970 | 5-9 |

| 3YZK1860 | 6000×1800 | 3 | ≤400 | 3-100 | 65-586 | 22 | 970 | 5-9 |

| 4YZK1860 | 6000×1800 | 4 | ≤400 | 3-100 | 65-586 | 30 | 980 | 5-9 |

| 2YZK2160 | 6000×2100 | 2 | ≤400 | 3-100 | 81-720 | 22 | 980 | 5-9 |

| 3YZK2160 | 6000×2100 | 3 | ≤400 | 3-100 | 81-720 | 30 | 970 | 5-9 |

| 4YZK2160 | 6000×2100 | 4 | ≤400 | 3-100 | 81-720 | 30 | 980 | 5-9 |

| 2YZK2460 | 6000×2400 | 2 | ≤400 | 3-150 | 100-810 | 22 | 970 | 5-9 |

| 3YZK2460 | 6000×2400 | 3 | ≤400 | 3-150 | 100-810 | 30 | 980 | 5-9 |

| 4YZK2460 | 6000×2400 | 4 | ≤400 | 3-150 | 150-850 | 37 | 980 | 5-9 |

| 2YZK2870 | 7000X2800 | 2 | ≤400 | 5-100 | 120-680 | 22x2 | 750 | 8 |

| 3YZK2870 | 7000X2800 | 3 | ≤400 | 5-100 | 180-720 | 22x2 | 750 | 8 |

| 2YZK3070 | 7000X3000 | 2 | ≤400 | 5-100 | 200-700 | 37 | 750 | 8 |

| 3YZK3070 | 7000X3000 | 3 | ≤400 | 5-100 | 230-800 | 45 | 750 | 8 |