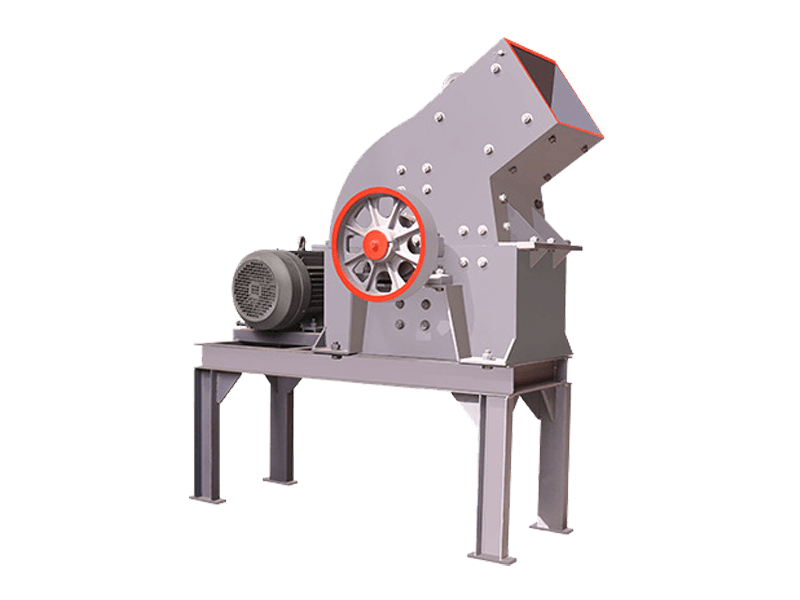

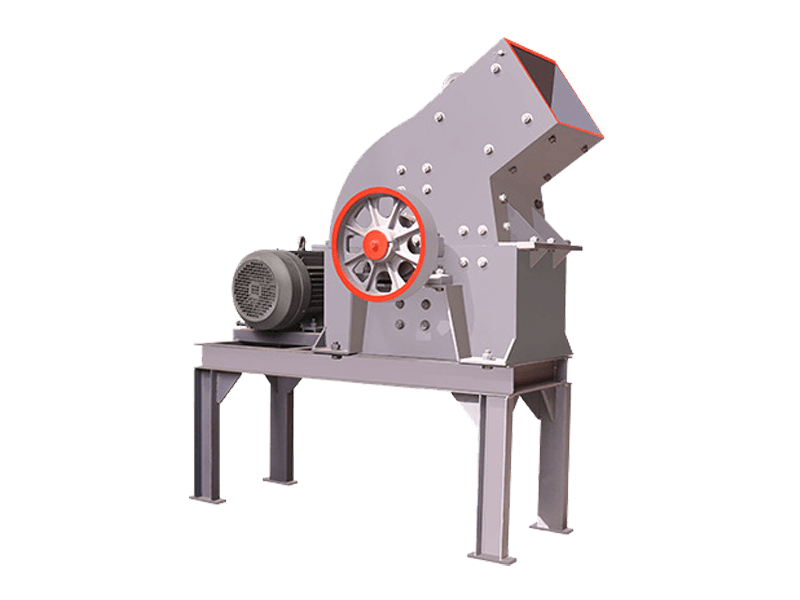

PC Hammer Crusher

Hammer crusher is also called hammer mill, or hammer crusher for short.

Capacity5-80t/h

Feeding Size≤500mm

Hammer crusher is also called hammer mill, or hammer crusher for short.

Capacity5-80t/h

Feeding Size≤500mm

Hammer crusher is also called hammer mill, or hammer crusher for short. It is a kind of equipment that crushes materials by impact. It is divided into two types: single rotor (single shaft) and double rotor (double shaft). Single rotor is divided into reversible and irreversible. It is mainly used in cement, chemical, electric power, metallurgy and other industrial sectors to crush medium and brittle materials.

01

Hammer head is wear-resistant and has a long service life

The hammer head of the hammer crusher is cast with a new process, has no internal cracks, is wear-resistant, has high compressive strength and a long service life

02

The particle size is adjustable to meet different operating needs

The gap between the grate bars can be adjusted according to user needs to change the particle size of the discharge material to meet the different needs of different users

03

Sealed design and dust reduction

The box of the hammer crusher adopts a sealed design, which solves the dust pollution and ash leakage problems in the crushing workshop.

04

Simple operation and convenient maintenance

The ring-type hammer head of the hammer crusher is easy to install. When replacing, you only need to open the cover and turn the hammer head. It is simple to operate and easy to maintain, which reduces the maintenance workload.

The main working part of the PC hammer crusher is the rotor with hammers. When working, the motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the crushing chamber of the hammer crusher from the upper feeding port, and is crushed by the impact, shearing and tearing of the high-speed rotating hammers. There is a screen plate at the bottom of the rotor. The crushed material with a particle size smaller than the size of the screen hole is discharged through the screen plate, and the coarse particle size larger than the size of the screen hole is retained on the screen plate and continues to be impacted and ground by the hammer until it is crushed to the required particle size and then discharged through the screen plate.

| Model | Feeding Size(mm) | Discharging Size(mm) | Capacity(t/h) | Power(kw) | Weight(t) | Overall Dimension(mm) |

| PCФ400×300 | ≤200 | ≤25 | 5-10 | 11 | 0.8 | 900 × 670 × 860 |

| PCФ600×400 | ≤250 | ≤30 | 10-22 | 22 | 2.26 | 1200 × 1050 × 1200 |

| PCФ800×600 | ≤250 | ≤35 | 18-40 | 55 | 4.8 | 1310 × 1180 × 1310 |

| PCФ1000×800 | ≤350 | ≤35 | 25-50 | 75 | 5.9 | 1600 × 1390 × 1575 |

| PCФ1000×1000 | ≤500 | ≤35 | 30-80 | 90 | 8 | 1800 × 1590 × 1775 |