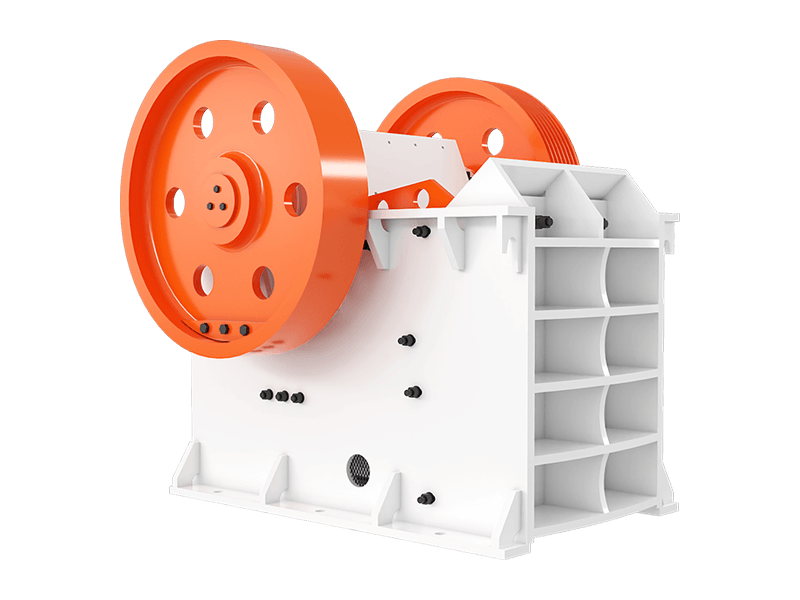

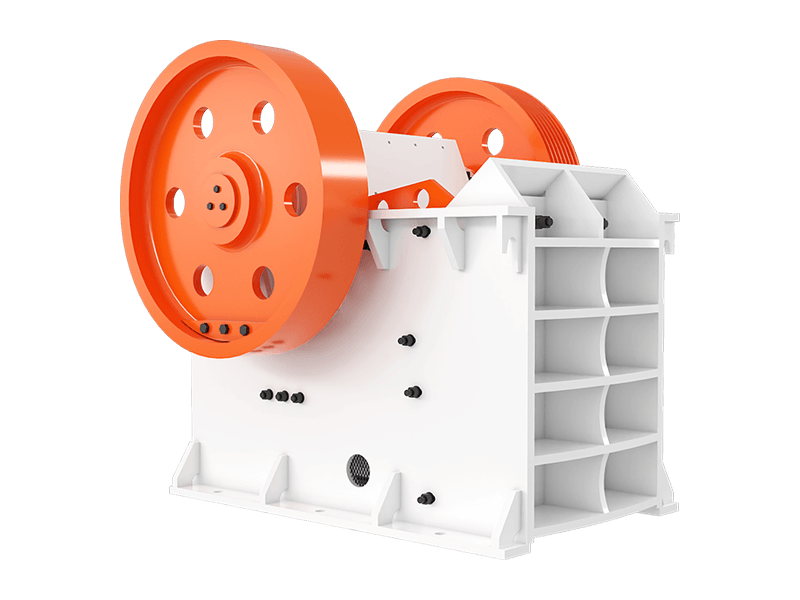

Jaw crusher

Jaw crusher has many advantages, such as big crushing ratio, equal product granularity, simple structure, reliable working condition, convenient repair and economical operation.

Capacity1-1000t/h

Feeding Size≤1200

Jaw crusher has many advantages, such as big crushing ratio, equal product granularity, simple structure, reliable working condition, convenient repair and economical operation.

Capacity1-1000t/h

Feeding Size≤1200

Jaw crusher has many advantages, such as big crushing ratio, equal product granularity, simple structure, reliable working condition, convenient repair and economical operation. It can be widely used in the works of mine, smelting, building materials, road, railway, irrigation, chemical industry, etc. The compression strength of the materials to be crushed is less than 320MPA.

1. Deep crushing cavity and energy efficiency.

2. Strong bearing capacity and stability.

3. Advanced technology and long service life.

4. Simple maintenance with the centralized lubrication system.

5. Simple structure and maintenance.

6. Wide range of the discharging adjustment and multi-purpose.

7. Little noise and dust.

1. Select the most high-end production materials.

Unique jaw-head structure, seal guarantee, extend bearing life.

2. High crushing strength, high production capacity.

Adopts finite element analysis technique, the crusher has higher crushing strength.

3. Unique flywheel design.

Unique flywheel design, reduce vibration effectively, machines work more stably.

4. Large bearing specification, high bearing capacity

All JC series jaw crushers are equipped with larger and more durable eccentric shaft bearings than other similar size crushers, their higher bearing capacity and effective labyrinth seals make the bearing service life be greatly prolonged.

5. Quick and easy to adjust discharging outlet.

Euro-type JC series jaw crushers are equipped with wedge block discharging adjustment devices, which are more simple, safer and faster than old models.

6. Deep-chamber crushing, high efficiency and energy saving.

Deep crushing chamber and no dead space, so to increase the feeding capacity with big crushing ratio and even particle size.

| Model | Feeding Size(mm) | Discharge Gatesize (mm) | Capacity(t/h) | Motor Power(kw) | Overall Dimension(mm) |

| PE150×250 | ≤130 | 15-45 | 1-4 | 5.5 | 896×745×935 |

| PE250×300 | ≤150 | 15-55 | 3-6 | 7.5 | 1050×987×1000 |

| PE250×400 | ≤210 | 25-60 | 5-20 | 15 | 1215×1520×1030 |

| PE400×600 | ≤350 | 40-90 | 15-60 | 30 | 1650×1588×1050 |

| PE500×750 | ≤425 | 50-100 | 40-110 | 45 | 1956×1918×1920 |

| PE600×900 | ≤500 | 60-125 | 90-180 | 55 | 2250×2733×2280 |

| PE800×900 | ≤600 | 80-140 | 100-220 | 75 | 2450×2950×2490 |

| PE750×1060 | ≤630 | 60-150 | 110-380 | 110 | 2531×2455×2783 |

| PE900×1060 | ≤700 | 100-160 | 230-390 | 110 | 2900×2657×2950 |

| PE900×1200 | ≤750 | 110-165 | 220-450 | 132 | 3100×2760×3260 |

| PE1000X1200 | ≤900 | 110-185 | 315-500 | 132 | 3200×2760×3260 |

| PE1200×1500 | ≤950 | 115-195 | 550-1000 | 220 | 3710×3446×4075 |

| PE1500×1800 | ≤1200 | 135-225 | 600-1200 | 280 | 5100×4700×4300 |

| PEX150×750 | ≤120 | 10-40 | 8-25 | 15 | 1310×1118×1145 |

| PEX250×750 | ≤210 | 15-50 | 15-35 | 22 | 1400×1751×1515 |

| PEX350×750 | ≤300 | 15-50 | 18-40 | 30 | 1485×1680×1648 |

| PEX250×1000 | ≤210 | 15-60 | 15-60 | 30 | 1550×1964×1380 |

| PEX250×1200 | ≤210 | 15-60 | 20-60 | 37 | 1530×1946×1380 |

| PEX300×1300 | ≤250 | 25-60 | 16-105 | 55-75 | 2000×2320×1730 |